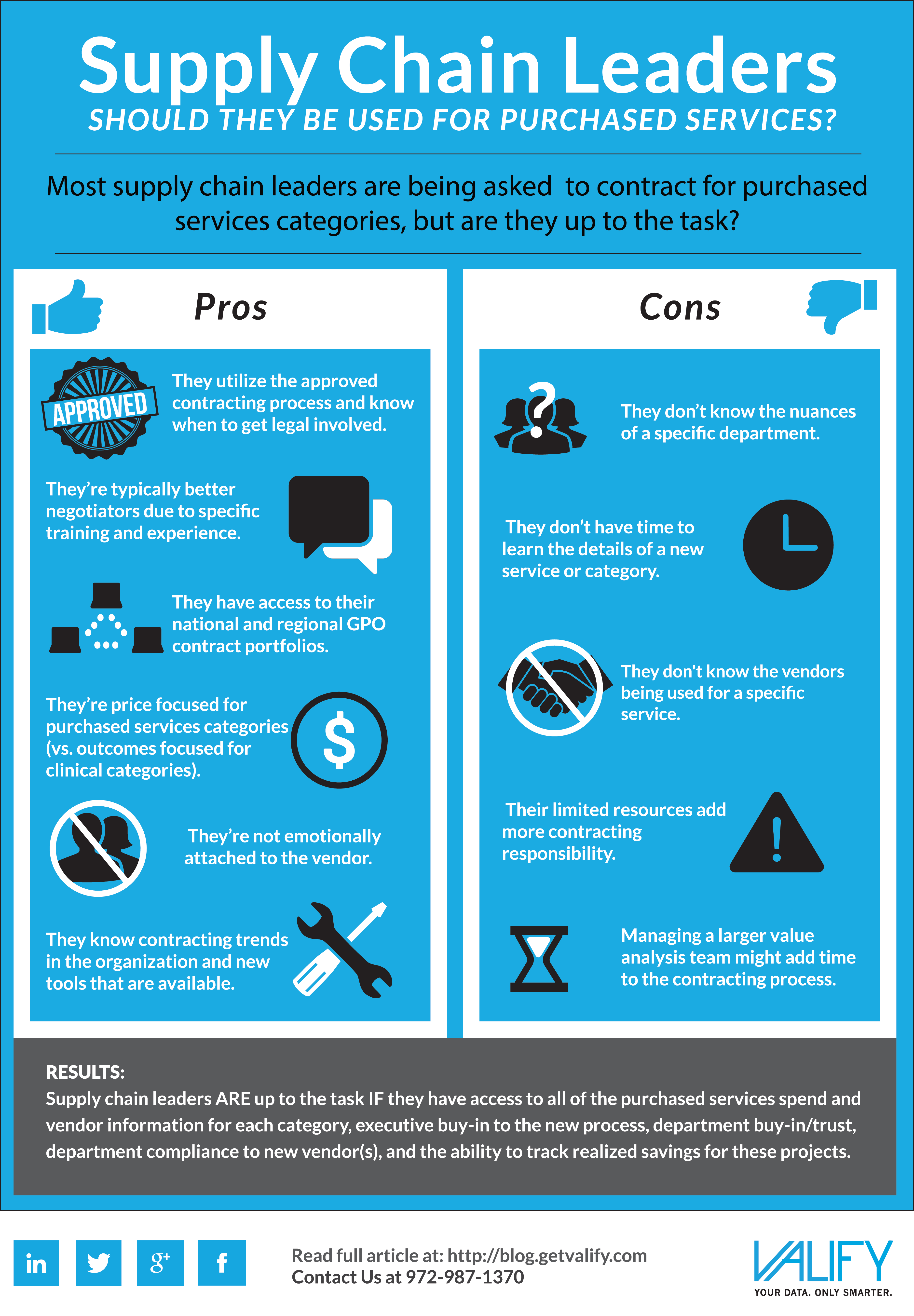

Most supply chain leaders are being asked to contract for purchased services, but are they up to the task? Although some purchased services categories are easy to understand (medical gas, EVS distribution, etc.), most require a completely different skill set or a unique process that is far removed from traditional materials management projects.

Historically, some departments that fall under the broad definition of purchased services (IT, HR, etc.) self-contract for their needs or tell the supply chain department which vendor to put on contract. This has led to massive amounts of waste, emotional attachments to vendors, and long-term/no-bid contracts. This is obviously the wrong approach to managing a high-performing organization.

But it happens…a lot. If this is your current process, you are in luck! There are huge savings opportunities in standardizing your contracting process to one department. You can then use the subject matter experts (SMEs) from the departments in the same way you would use clinical experts for their input in most medical and PPI product categories.

Value Analysis Process

This approach is called using a value analysis process. The value analysis process is what the best-in-class organizations are utilizing for all of their contracting decisions now. They are required to send all contracts through their supply chain or contracting department to make sure their approved contracting process is being utilized every time…and they are reaping the rewards.

It is also a great way to keep the department happy (and increase their commitment) because they get to have a say in the entire process. This is their world and they won’t like part of it being taken away so being able to explain that they are going to be involved in the process will help eliminate any pushback.

How Does This Work Exactly?

Let’s take the process of buying laptops for example. Currently, most IT directors handle this process, and they typically have a few different standard configurations of laptops to choose from based on where the laptop will primarily be used. For example, they might have executive, clinical and administrative configurations. So far, everything looks good. The problem arises when they require all of these laptops to be brand specific (i.e. They must be Dell, IBM, etc.). If you ask them why, they will most likely say that they are a Dell shop. If you ask them why again, you will hear some version of an emotional attachment to them because of past performance or a bad experience with other brands.

This is where the savings opportunities are hiding. Over the past several years, the differentiators between the larger brands have started to disappear, so loyalty to a specific brand starts to be less important. What you need to do is have your IT Director send you the details of those 3 standard configurations, so you can take those configurations out to bid to all of the OEMs and IT Resellers.

Once the bids are back, have your IT Director agree that the proposed configurations meet their needs (just like having a physician agree that a product is Clinically Equivalent). Once they’ve agreed, then it just comes down to negotiating the contract with the vendor that provided the best value. It’s a business decision now and not a specialized skill that requires the IT Director.

You can do this for every category in your health system. Once you show the savings to the department and that the quality has not decreased, they will be on your side because you are taking a lot of work off of their plates. Trust me, they dont want to spend their time sending out RFPs and negotiating contracts. You and your team are professional negotiators and bring experience from hundreds of RFPs, so why would your organization burden them with these tasks?

5 Tips to Maximize Savings

To summarize, I think supply chain leaders are up to the task to contract for purchased services categories/vendors if they have the following tools to help them:

-

Easy access to all of the purchased services spend and vendor information for each category

-

Executive buy-in to centralize the contracting process (most likely needs to come from the CEO since the CIO and HR executive might report directly to him/her)

-

Department buy-in/trust in the process

-

Department compliance to the newly awarded vendor (it doesn’t work if the volume does not move to the new vendor)

-

The ability to track savings for these projects (this will prove if the process is working or not)

image source: istock